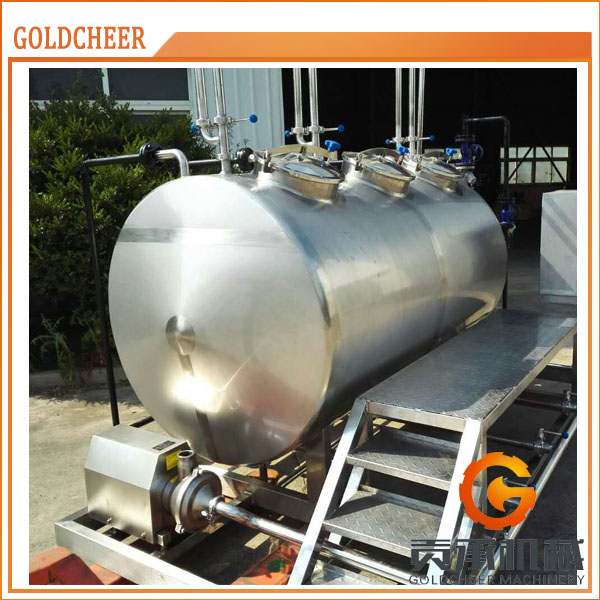

CIP system

Integrated CIP system

Description:

CIP system is used for cleaning of milk, beverage, beer, fruit juice processing line to guarantee the sanitary requirement of the machines.

CIP system is consisting of acid tank, soda tank, water tank, CIP pump, steam system and electric control system.

- Technical Parameter

- Characteristic

|

Model |

YCIP-0.3 |

YCIP-0.5 |

YCIP-1 |

|

Acid tank |

300L |

500L |

1000L |

|

Soda tank |

300L |

500L |

1000L |

|

Water tank |

300L |

500L |

1000L |

|

Capacity of pump |

10m3/h |

10m3/h |

10m3/h |

|

Height of pump |

36m |

36m |

36m |

|

power |

3kw |

3kw |

3kw |

Products

Contact Us

- Tel: +8613817992833

- Fax: +86-21-39532060

- Mobile: +8613817992833

- Whatsapp: +8613817992833

- Wechat: +8613817992833

- Email: mark@berggruentech.com

- Address: No.178 Minke Road, Baoshan District, Shanghai, China