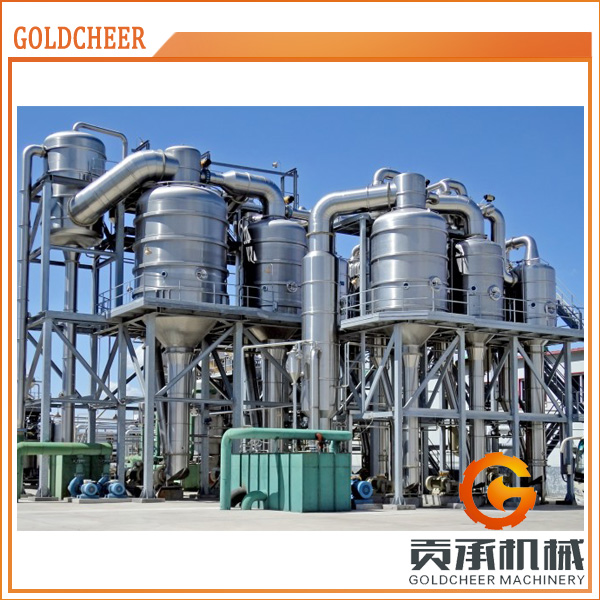

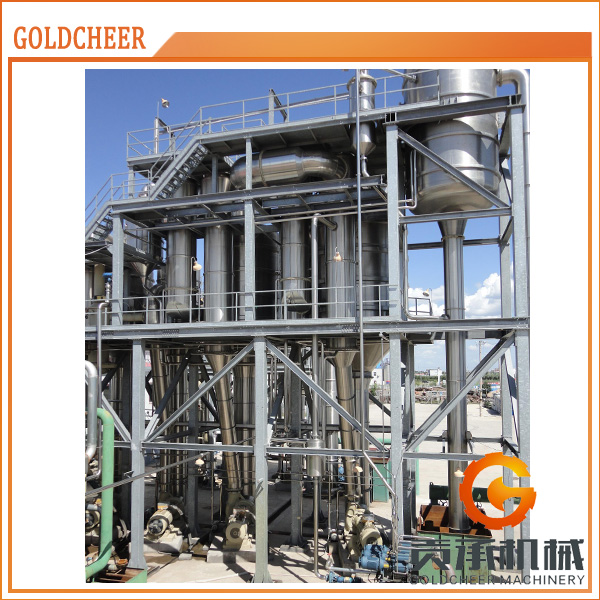

Fruit Jam Vacuum Evaporator

Description:

Fruit jam vacuum evaporator is applicable for heat-sensitive, high-viscous material such as tomato paste, mango puree, guava puree, passion fruit puree, blackberry puree and the other fruit puree.

It can in low-temperature continuous concentration under vacuum. The mainframe is composed of heater, evaporating chamber, hydraulic sprayer, multi-level pump water tank, circular out-feed pump and operation platform.

Low temperature makes the end products have better color, flavor and nutrition.

Products feeding, temperature control, products brix control, cooling water discharge is controlled automatically in the whole and manual control separately.

The main frame is composed of heater, evaporating chamber, multi-level pump, water tank, circular out-feed pump and operation platform.

- Technical Parameter

- Characteristic

|

NO. |

Capacity (Ton/day) |

Evaporating Capacity (Kg/h) |

Electricity Consumption (kw/h) |

Water Consumption (t/h) |

Steam consumption (kg/h) |

|

1 |

150 |

5300 |

105 |

150 |

2120 |

|

2 |

300 |

10560 |

190 |

300 |

4300 |

|

3 |

400 |

13800 |

197 |

400 |

5600 |

|

4 |

500 |

17280 |

205 |

500 |

7200 |

|

5 |

600 |

20700 |

380 |

600 |

8300 |

|

6 |

800 |

27600 |

394 |

800 |

11500 |

|

7 |

1000 |

34560 |

410 |

1000 |

14000 |

|

8 |

1200 |

41400 |

591 |

1200 |

17000 |

|

9 |

1500 |

51840 |

615 |

1500 |

23800 |

Contact Us

- Tel: +8613817992833

- Fax: +86-21-39532060

- Mobile: +8613817992833

- Whatsapp: +8613817992833

- Wechat: +8613817992833

- Email: mark@berggruentech.com

- Address: No.178 Minke Road, Baoshan District, Shanghai, China